PRODUCTION

APS Arosio S.p.a. stands out for its extreme manufacturing flexibility and customer service, with which it can make products designed based on the client's specific needs and reference market.

Each one of the group's manufacturing site is structured to autonomously manage all processing stages, ensuring quick production time and delivery of materials, even for customized jobs. To promptly respond to clients' requests, APS Arosio SPA ensures the following services:

• CUTTING

Supply of profiles matching the client's specific length request. This is a technically simple and yet very useful operation to ensure the most efficient service, as it considerably reduces costs for the client's production cycle.

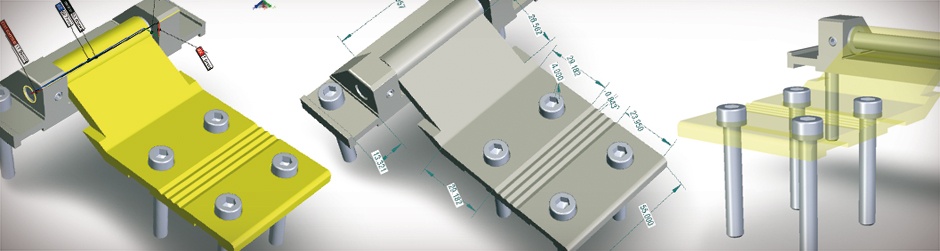

• NUMERICAL CONTROL WORKING CENTRE

In our plant in Milan we have introduced a numerical control working centre to conduct mechanical processing such as drilling, threading and milling on profiles up to six metres long. A top professional service provided to meet the most demanding of requests.

• ASSEMBLY

Preparation of pre-assembled semi-finished products aiming to make the assembly of the systems easier for the client. Special attention is given to the dampers, flexible duct connectors, droplet separators, louvers and frames.

• WAREHOUSE

APS Arosio S.p.a. keeps in stock all the products in its catalogue. The company's philosophy is to deliver the product as soon as possible. This is why each production site has a logistics structure with suitable areas and equipment to ensure service to the client in a short space of time.

Each one of the group's manufacturing site is structured to autonomously manage all processing stages, ensuring quick production time and delivery of materials, even for customized jobs. To promptly respond to clients' requests, APS Arosio SPA ensures the following services:

• CUTTING

Supply of profiles matching the client's specific length request. This is a technically simple and yet very useful operation to ensure the most efficient service, as it considerably reduces costs for the client's production cycle.

• NUMERICAL CONTROL WORKING CENTRE

In our plant in Milan we have introduced a numerical control working centre to conduct mechanical processing such as drilling, threading and milling on profiles up to six metres long. A top professional service provided to meet the most demanding of requests.

• ASSEMBLY

Preparation of pre-assembled semi-finished products aiming to make the assembly of the systems easier for the client. Special attention is given to the dampers, flexible duct connectors, droplet separators, louvers and frames.

• WAREHOUSE

APS Arosio S.p.a. keeps in stock all the products in its catalogue. The company's philosophy is to deliver the product as soon as possible. This is why each production site has a logistics structure with suitable areas and equipment to ensure service to the client in a short space of time.